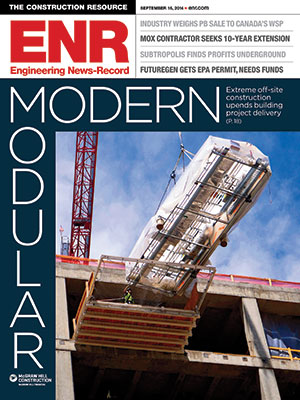

建筑物编辑Nadine M. Post最近的封面故事,“模块化建筑的承诺和陷阱,”和相关文章,“莫滕森使用场外建设来加快丹佛医院的分娩,”“ Project Frog的零件套件方法可以通过避免卡车运输限制来更好地设计”和“尽管面临挑战,但堆栈的开发人员认为模块化是必经之路。”attracted a number of comments and kudos. The letters follow:

Call for Less Cheerleading and More Critical Observation

模块化部门需要更少的啦啦队和更批判性的观察,因此我感谢Enr发表这篇经过深入研究和信息丰富的文章。新利18备用

Despite the challenges, the reason the modular sector will continue to grow is because a well-organized plant is a much more productive work environment than a construction jobsite. Combined with the fact that per hour, labor on jobsites is more expensive than shop labor, firms with prefabrication skills have an increasing competitive edge over conventional builders.

Following this logic to its ultimate conclusion, a greater percentage of work completed in the plant equals greater savings. Since the transportation and hoisting costs for a complete unit are about the same as for the bare frame, a module should have the greatest possible amount of labor and materials embedded before it leaves the plant.

出于这个原因我不能同意这个建议that the B2 modules are “too complete.” If there are problems with the fit of the façade panels, it is likely because of accumulating tolerances, rather than excessive “completeness.” So the goal was noble, the execution lacking. In fact stacking factory-built volumetric modules provides builders with a golden opportunity to produce precise building geometry in a plant and then export that geometry to the site. Far easier than shipping random geometry to a site, then trying to survey the variations and knock the building into line before tacking on more bits.

On the topic of plant organization, moving boxes down a line is not inherently better or worse than moving workers among the boxes. Assembly lines are expensive to set up and they don’t work well if the product is diverse. B2 modules vary from small triangles with no mechanical-electrical-plumbing systems and lots of facade, to large modules with kitchens and bathrooms. So having all the module types go down the same line would make it difficult to equalize dwell times at each station, not to mention the issues with just-in-time feeding of such a wide array of variants.

On the other hand, a plant making hundreds of nearly identical labor camp modules is well suited to an assembly-line approach. A month ago, I toured a three-tiered modular plant where workers fabricated walls on a loft, then fed them to the assembly line like slices of bread going into a toaster. Meanwhile other workers simultaneously completed underfloor assembly from a pit in the plant floor. A week ago, I was in a plant that shipped 16-ft-wide modules on custom trailers to local building sites. In other words, the correct approach to plant design is to match the factory building, the product and the process.

By including such a wide range of experiences, the article touches on a topic dear to our hearts, which is standardization. With the goal of eliminating the expensive and neverending cycle of invention, experimentation and disappointment, we have been working for two years to develop a flexible yet standardized approach to modular construction. The product we developed is called Vectorbloc. We welcome the opinions of ENR readers and invite anyone with questions to get in touch.

朱利安·鲍伦

总统

Vector Praxis

多伦多

Sobering History

Just read your very comprehensive articles on modular construction. I thought the details and comments that you received from your interviews were to the point.

很少有采访完全同意预制的好处,这一事实证实了我作为工程师在1970年代生产纽约市住房的混凝土模块时的经验。我与纽约住房合作伙伴关系的凯西·王尔德(Kathy Wilde)合作。我们生产了薄的壳混凝土盒,该盒子创建了12英尺宽的40英尺长的盒子。所有生产都是在我们在新泽西州科尔尼的工厂中完成的。

最初是由当时的住房和城市开发部长乔治·罗姆尼(George Romney)带入建筑行业的模块和预制梦想。罗姆尼(Romney)先生是密歇根州前州长,看到了汽车组装线建设的好处。

1969年,他发起了突破性的突破 - 旨在通过工厂模块化建筑技术增加负担得起的住房数量。鼓励大约20名进入行动突破的决赛入围者来完成他们的系统。当今的20个系统都没有。

I was honored to meet a number of pioneers in the business. The common factor amongst all of us was that we all thought modular housing was the wave of the future and with very few exceptions these manufacturers spent their own money on this concept.

作为工程师,我将自己沉浸在过程的各个方面,并希望分享我的一些观察结果。模块化的价值是,每个子系统(例如管道堆栈和加热系统)系统化了每个子系统,将这些子系统易于放置在通用框中。

The time and motion study clearly shows that repetition of process does increase efficiency. Owning a plant and not having a steady source of market is a great detriment to production. Waiting for orders can eat you up with plant and staff inefficiencies. The builder frequently gets the benefit of the manufacturer building the module while site and foundations are in place. Last but not least, one must have a module which when stacked must have an exterior structure to avoid the modules having to support the ones above. We did have a HUD approval for a system which used the concrete boxes as in-situ forms.

我们发现的最后一个但重要的事实是,该模块必须完整80%,以使其具有可持续性。

Vincent Desimone

DeSimone Consulting Engineers

纽约市

离开- 站点正确

我最近阅读了您的文章“模块化建筑物的承诺和陷阱”,很高兴看到,尽管涉及模块化构造的许多问题,但有一些“正确的现场构造正确”的例子,包括相关文章在您的网站上。我想提供另一个示例,说明“现场施工正确”。

我相信可以肯定地说,由于您的文章中提到的所有原因,模块化的建设将变得越来越普遍,这是由于能够在美国建造优质建筑的熟练工人的赤字越来越不足。我很幸运的是,我与一些真正的有远见的人一起工作,他们看到这种趋势变得更接近规范,并掌握了自己,以弄清楚如何通过组建一个名为oftanel的技术来弄清楚它。

止马蹄铁技术由来自全国各地的一群承包商组成,他们在单个横幅下作为分支机构聚集在一起,提供工厂建设的建筑物外部。这些承包商都使用一套通用的细节和规格来构建各种墙壁系统。

因为他们都使用相同的材料并遵循相同的指南进行施工,所以他们能够相互共享最佳实践,并利用每个附属公司带来的不同专业知识领域。这些分支机构中有一些数十年来一直在建造场外建筑外部,而有些则是任何类型的异地建筑。

The combined wealth of knowledge and the shared resources amongst the group are what allows each affiliate to avoid the exact pitfalls pointed out in your article. The combination of highly skilled contractors and years of experience with off-site construction has already helped StoPanel Technology realize some amazing projects that boast fast, green, safe and cost-effective construction.

知道模块化构建只会继续增长,我会指出,Stopanel技术是一个以身作则的团队。我必须相信那里还有其他志趣相投的人,我很想在将来听到更多他们的故事。

约翰·张伯林

产品经理

Sto Corp.

亚特兰大

Well Researched

Thank you for a very well researched and informative article about the current state of modular construction and the status of the B2 project. We as an Industry appreciate your efforts.

Tom O'Hara

业务发展副总裁

Capsys Corp.

布鲁克林,纽约