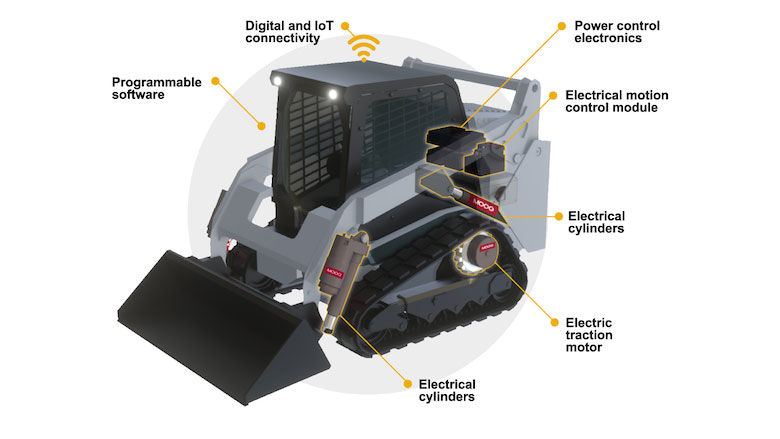

Bobcat Co.在一月份的消费电子节目中脱颖而出,揭幕了该公司新的全电动紧凑型轨道装载机T7X,不仅抛弃了柴油发动机,而且还抛弃了整个液压系统。尽管许多设备制造商都将电动概念机作为一次性的努力,但山猫将电气化视为该行业的广泛转变。

Bobcat Global Innovation副总裁Joel Honeyman表示,T7X与电动汽车制造商Moog Construction合作开发,旨在超越建筑设备领域的一些电气化工作。

“This was two leaps of technology,” he explains. “We not only added the battery, but we’ve added other levels of electronic controls.”

Replacing the compact track loader’s traditional hydraulics with electric actuator motors offers a different power curve than on an ordinary machine, but Honeyman says it's the result of a long journey. Bobcat North America had developed a prototype electric compact track loader in 2019 but kept refining it to get where it is today.

霍尼曼回忆说:“我的首席工程师有一天出现,说有些公司会进行电动驱动。”“我们知道液压学的作用,永远存在。但是,如果我们全力以赴,还有其他固有的优势。”

With the hydraulics replaced, the TX7 has reduced vibration compared to conventional models, and like other electric vehicles, is much quieter during operation. The electric actuators also behave differently than hydraulics, so operators will have to get used to it, says Honeyman. “Once you activate it on the joysticks, that machine will go—you’ve got full torque when starting at zero speed and zero rpm,” he says.

Image courtesy Bobcat Co.

The T7X also has a setting for a “beast mode” that allows for full power and torque on demand, but Honeyman says it will only work at certain arm and bucket positions to prevent damaging the machine. In fact, the electronic controls are able to monitor the draw during operation and prevent the operator from accidentally damaging the machine.

“Say that you're rolling back the bucket and a rock is caught in the actuator,” Honeyman says. “With hydraulics you can’t see it and could damage the machine. [With the T7X] we can sense it and have the motors back off.”

Allowing the machine to proactively avoid damage can prolong its life and avoid costly repairs, he adds.

Ease of Operation

操作也已简化。消除柴油发动机意味着没有柴油加油,同时消除液压系统意味着没有液压液可以卸下。Moog Construction的总经理Joe Alfieri表示,虽然零排放机具有生态利益,但全电动也可以打开T7X和其他设备,以更轻松的自动化。

“Once you have an electric machine, it becomes very controllable, like a robot,” he says. “You can load software to have it do things at that point. [Electrification] enables higher levels of automation.”

The T7X is built to roughly the same form factor as Bobcat’s T76 conventional compact track loader, although the electric model is about 1,000 lb heavier. It can be charged from standard EV-charging ports and will fully charge overnight. The current version is capable of four hours of continuous runtime, with an eco mode to save power.

Because it’s all batteries and electric motors, the idle power consumption is very low, points out Honeyman. “As soon as you let off the joysticks, it is not consuming energy. It’s not running at idle like a diesel machine,” he says. “A lot of customers forget that.”

Bobcat will make the initial group of T7X electric compact track loaders available through Sunbelt Rentals later this year. These initial machines run at a cost nearly three times that of a traditional model—at more than $200,000 each—but Honeyman says the price is likely to drop as Bobcat expands production of electric machines.