“这是如何bridge still standing?”

亚伦的最初反应秸秆,麦克风hael Baker International’s vice president and regional bridge practice lead, as he first studied images of a fractured tie beam that forced the May 11 emergency shutdown of the I-40/Hernando de Soto Bridge between Tennessee and Arkansas. Discovered earlier in the day during MBI’s routine above-deck inspection, the fracture on the bridge’s eastbound span affected nearly half the cross-section of a 26-in. by 33-in. welded girder supporting one of the 50-year-old structure’s 900-ft-long, 100-ft-high arched navigation spans across the Mississippi River.

MBI国家桥技术总监弗兰克·鲁索(Frank Russo)表示,尽管旧结构发生了组件裂缝,但De Soto Bridge裂缝仍然令人困惑。绑带的0.5英寸厚的顶部法兰板和外部1-3/8英寸厚的网板完全切断,裂缝延伸到底部法兰板的近一半。此外,将内部网与上法兰连接的9英尺焊缝也分开了。

.jpg)

Shortly after the fracture was discovered, the 900-ft-long bridge spans were closed and inspections began. Here, workers are taking part in the early stages of phase 2 repair work.

照片由Michael Baker International提供

“Usually when something like this breaks, you find it completely broken,” Russo says. “It’s very remarkable that this member didn’t completely fracture.”

Though the fissure’s cause and characteristics remain under investigation, two things were clear as the bridge was immediately closed to traffic—its condition needed to be thoroughly assessed in the event there was additional damage, and a repair strategy needed to be developed as quickly as possible.

The fracture, discovered on May 11, caused an immediate emergency shutdown of the bridge.

照片由Michael Baker International提供

Despite the fracture’s extraordinary aspects, there is a strong familiarity among the team tasked with carrying out the assessment, both with the de Soto Bridge and with each other. The Arkansas and Tennessee transportation departments have long shared responsibility for the structure, with ARDOT overseeing inspection and TDOT handling maintenance. MBI, which would lead the response’s aerial inspection and design work, had worked with both agencies, as had HNTB, which performed a full hands-on inspection of the below-deck areas of both tied-arch spans. Experts from the Federal Highway Administration were also involved.

An inspector gets a close-up view of the fracture.

照片由Michael Baker International提供

“It’s very remarkable that this member didn’t completely fracture.”

—Frank Russo, National Bridge Technical Director, Michael Baker International

“That gave us a deep bench of structural engineering expertise and resources, allowing for a significant amount of analysis and design to take place in a very short amount of time and with a high level of reliability and accuracy,” says ARDOT spokesman Dave Parker.

该团队还采用了技术,使用了无人机视频与使用绳索访问技术的物理检查相结合,以加快病情评估。无人机还允许对骨折的物理检查实时流向基于办公室的设计团队。

“We could see what the inspector was doing and ask to check out additional aspects, which helped us start planning multiple steps ahead,” says MBI bridge technical director Jason Stith. “It was quite incredible to get that information during a two-hour conference call rather than having to go back and forth over several days.”

此图显示了检查员首次发现裂缝时的视图。

Photo courtesy Tennessee Dept. of Transportation

田纳西州和阿肯色州之间这种重要联系的紧急情况要求工作以24/7的基础进行。

Photo courtesy Kiewit

Multi-path Planning

尽管在桥上没有发现额外的损坏,但深入的检查表明,裂缝处的结构负荷已被剥落到剩余的网和法兰部分,使这些组件处于特殊的压力下。

斯托弗说:“我们需要更好地理解这一点,然后才能在桥上猛拉,试图将事情转移回它们的位置。”

As the team began concurrent design efforts to stabilize the structure and devise a permanent repair, TDOT implemented an emergency construction manager/general contractor procurement that agency commissioner Clay Bright says had the capability “to get involved in the difficult, challenging and at the time, still unknown final repair design.”

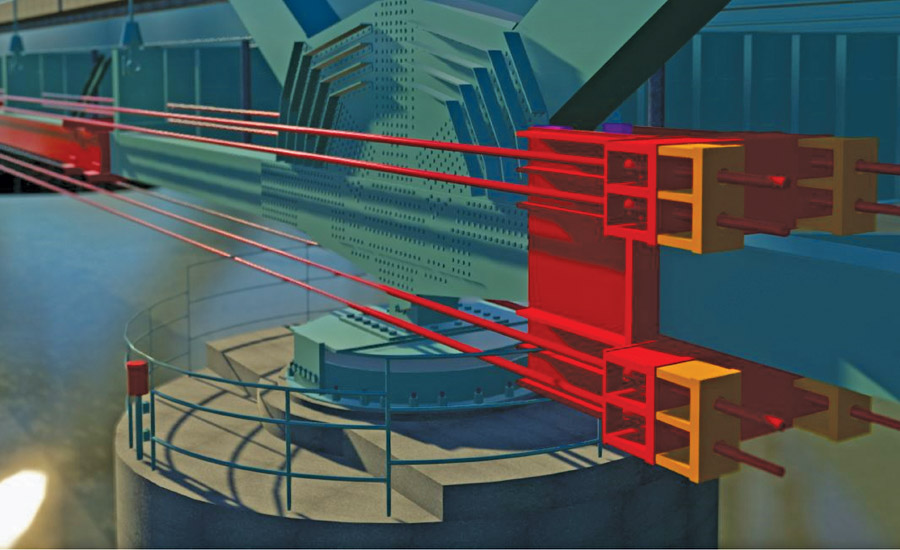

Conceptual rendering of Phase 2 post-tensioning scheme used during the repairs to the structure.

Rendering courtesy Michael Baker International

5月17日下午,在TDOT选择Kiewit参加该项目之后不到两个小时,运营副总裁兼地区经理Chris Frieberg和其他公司代表正在与设计团队讨论稳定和维修替代方案。

“We worked through risks associated with different design options and the best way to mitigate them, as well as material availability and fabrication lead time,” Frieberg says. He adds that the solution had to be one the design team could stand behind and his team could build safely.

Rendering courtesy Michael Baker International

“And it had to be permanent, so that the DOTs would be assured of having a safe structure for years to come,” he adds.

由此产生的两相策略要求首先用“夹板”的钢板板稳定裂缝区域,从而增加结构的冗余。由于梁略微扭曲并扭曲,因此板将被抵消以防止对该区域施加任何新的压力。

While TDOT originally envisioned basing the repair effort from barges, the design team’s loading analysis indicated that the fracture area could be safely accessed from the bridge deck.

“That gave us a more controlled environment for the delicate work we were doing, although we did have to keep personnel and equipment to a minimum,” Frieberg says.

By the end of that first week, Kiewit had assembled a 100-sq-ft suspended platform to install the first of 30,000 lb of HPS70W structural steel plates fabricated on an expedited basis at Stupp Bridge Co. in Bowling Green, Ky.

Over the next four and a half days, crews used chain and air hoists to lift the plates into place, where they were secured with nearly 450 temporary bolts. Frieberg says the work involved some lead paint considerations and confined space protocols when working inside the tie beam but required no additional measures for COVID-19.

使用无人机检查损坏的桥梁的能力为项目团队提供了帮助。

从stopgap到结构声音

5月14日,在发现裂缝后仅三天后,De Soto桥被认为足够稳定且安全,以使TDOT重新开放底层河道以驳船交通,然后过渡到下一个维修阶段。围绕裂缝区域的150英尺长的绑带梁将用108,000磅的额外冗余板加强,并在横梁上安装了八个3英寸3英寸,高强度的,张紧后的杆,以转移更多复合部分的紧张张力超过120万磅。

补充后的张紧还使工人可以去除骨折的法兰切片进行分析。

鲁索说:“如果整个领带决定打破,这不太可能,它的外部有一个完全多余的元素,可以承受负载。”

弗里伯格说,由于必须同步的专业后张紧组件和焊接的精确制造,因此需要更高水平的协调和分析,并且必须同步与动员专业分包商同步并满足其他物流需求。

“We had three critical paths running simultaneously, and the art of the dance was keeping them all in unison,” he says. “All three converged so that as the design was signed and sealed, material fabrication was underway.”

By July 3, the last of the plates at the fracture location had been bolted into place. But there was still one more important step to complete before the bridge could be declared fully restored. During the initial condition inspection, HNTB conducted non-destructive phased array ultrasonic testing on the tie girders’ 500 welds to determine if similar cracks were forming or could form under certain conditions. Seventeen welds were found to have anomalies, which Kiewit plated over the next three weeks with a total of 78,000 lb of steel to provide additional redundancy. Another 29 weld defects were ground or cored out.

“It had to be permanent so that the DOTs would be assured of having a safe structure for years to come.”

—Chris Frieberg, Operations Vice President, Kiewit

经过另一轮检查后,德索托桥的东行车道于7月31日重新开放到交通,两天后是西行车道。这完成了为期83天,24/7马拉松比赛,没有天气中断。新利18备用官网登录这两个点将分担常规和专业检查和维修的成本,目前估计为1000万美元。

The effort also concluded what ARDOT’s Parker considers to be a parallel success story—safely shifting the de Soto Bridge’s 40,000 vehicles per day to other crossings, particularly the nearby 72-year-old truss bridge that carries I-55 across the river.

Parker credits the team’s collaborative brainstorming of congestion relief strategies for helping cut the I-55 bridge’s initial hour-long peak-hour backups by more than half and reducing bail-out traffic onto local roads. Both DOTs stepped up services to minimize the effects of lane-closing incidents. TDOT’s Bright notes that motorists’ initial concerns about the safety of the I-55 bridge were alleviated by emergency inspections and the performance of the “robust structure” while the de Soto Bridge was out of service.

“The only issue was a pavement failure in one lane that was quickly addressed during a weekend temporary lane closure,” Bright says, adding that the bridge is currently undergoing its scheduled biannual inspection. “Any new issues will be addressed along with other maintenance work next spring.

Meanwhile, the fractured tie girder section is at Wiss Janney Elstner’s forensic laboratory in Northbrook, Ill., undergoing metallurgic and other tests in an effort to fully understand the factors that led to the fracture. Parker says results of that investigation, scheduled to be delivered by fall, will help the DOTs determine if the structure requires additional attention on top of regularly scheduled inspections and maintenance. A solar-powered strain gauge monitoring system installed prior to the bridge’s reopening also remains operational.

What’s already certain, team members agree, is the essential role team-wide collaboration played in turning a potential catastrophe into a success story.

“If you listened into our daily calls, you wouldn’t have been able to tell who was DOT, who was designer and who was the contractor,” Frieberg says. “Going through the process, we were very well integrated and very open-minded. That was the biggest contributor with coming up with a design solution that could be implemented quickly and safely.”

Questions Remain in Inspection Oversight Controversy

Within hours of the discovery of the de Soto Bridge tie girder, images and video emerged suggesting that the fissure had been months, perhaps even years, in the making despite having been unreported in at least two ARDOT-led annual fracture-critical inspections. Following an internal investigation launched immediately after the closure, ARDOT fired Monty Frazier, a 15-year employee who had led the 2019 and 2020 de Soto Bridge inspections. In addition, the Federal Highway Administration launched an assessment and compliance review of ARDOT’s bridge inspection program, with the results expected by the end of September.

Frazier’s reported assertion that the mobile under-bridge inspection platforms were unsafe to use was countered by the agency’s heavy bridge maintenance staff (HBMS), which, according to an ARDOT interim after-action report, verified that the equipment was stable and provided adequate access to perform hands-on inspection at the fracture location. Nine other fracture structures inspected by Frazier were reexamined and found to be safe.

Frazier has since admitted that missing the fracture was a mistake on his part, but he insists he’s not solely to blame. In an interview with the Daily Memphian newspaper, published on July 22, Frazier said he pointed to the crack’s appearance in photos reputedly dating as far back as 2014 as proof that other inspectors overlooked the condition as well. “If there are that many people who missed the crack over all that time,” Frazier told the reporter, “it’s a problem with the way we inspect the bridge, not just the one guy who happened to be on the paperwork the last time we missed it.”

ARDOT has not verified the validity of the photos and declined to comment on the story. Meanwhile, multiple investigations are underway, including an agency-requested probe by the U.S. Dept. of Transportation’s Office of Inspector General as to whether Frazier’s alleged negligence constitutes a criminal action. A parallel internal investigation by ARDOT’s human resources department is proceeding as well.

7月,Ardot将其历史悠久的桥梁维护系统预算提高了近300万美元,为顾问提供了资金,这些顾问将帮助该机构确定新技术,提高质量保证和质量控制并改善检查员培训。